Powering Protection for Battery System Components

Ensure the safety, cleanliness, and performance of your NEV battery systems with our advanced protective solutions. From high-voltage connectors to cooling interfaces, we help safeguard critical components during assembly, transport, and integration.

HV & LV Interface Protection

Cooling Plate & Spigot Sealing

Cleanroom-Ready Components

Cleanroom-Ready Components

Protecting Performance in Battery System Components

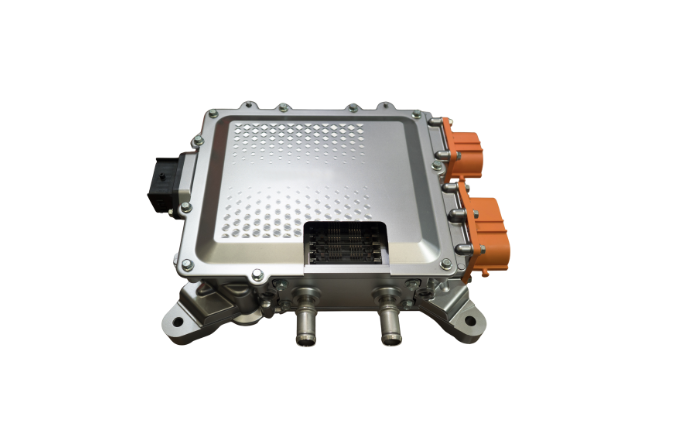

Battery systems are the energy core of NEVs — integrating high-voltage distribution, thermal management, and intelligent monitoring. From battery junction boxes to cooling plates and BMS interfaces, each element must be protected to ensure safety, efficiency, and long-term reliability.

Our protective solutions are engineered to meet the evolving needs of battery architecture, supporting cleanroom compliance, ESD safety, and ergonomic handling in high-volume production environments.

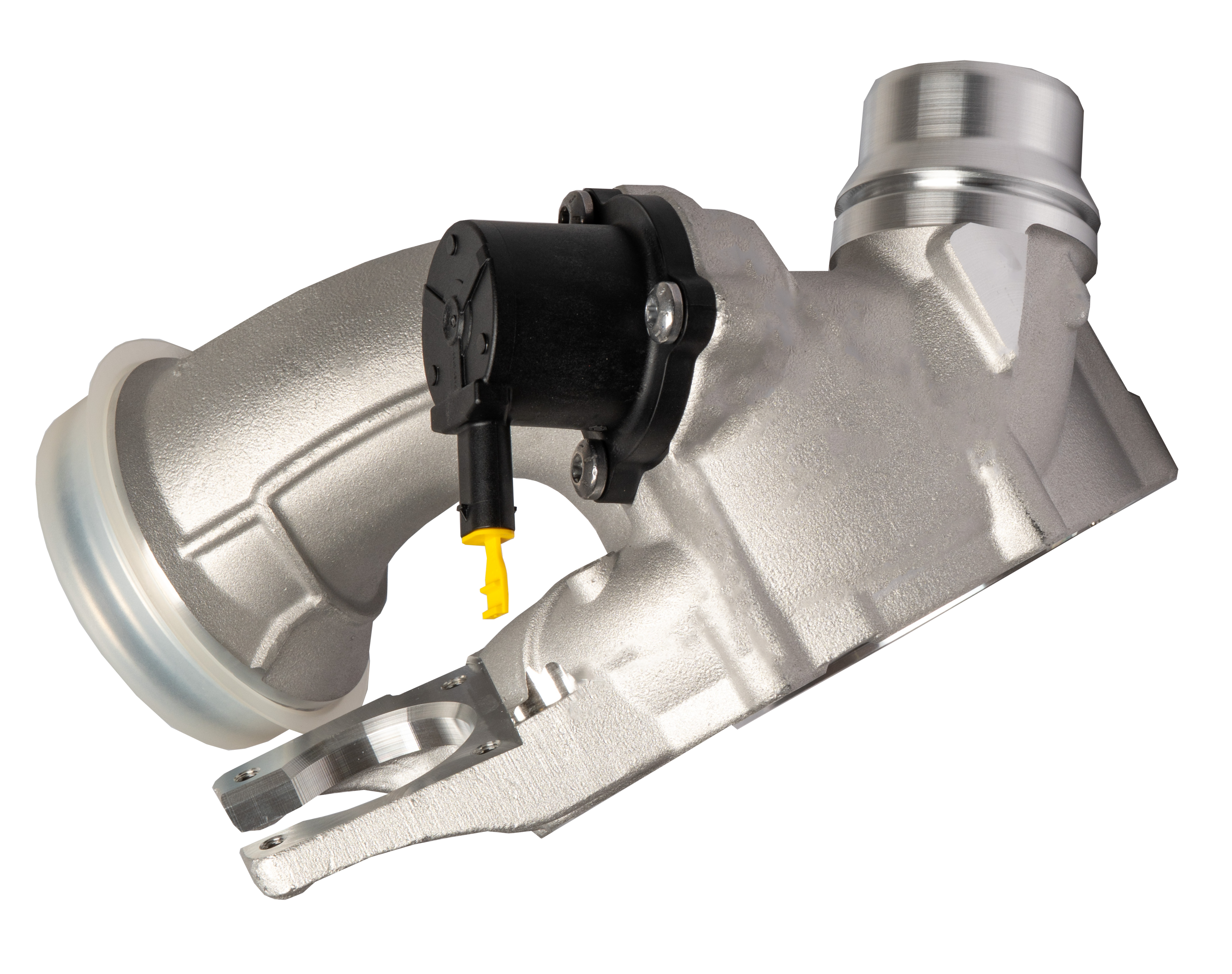

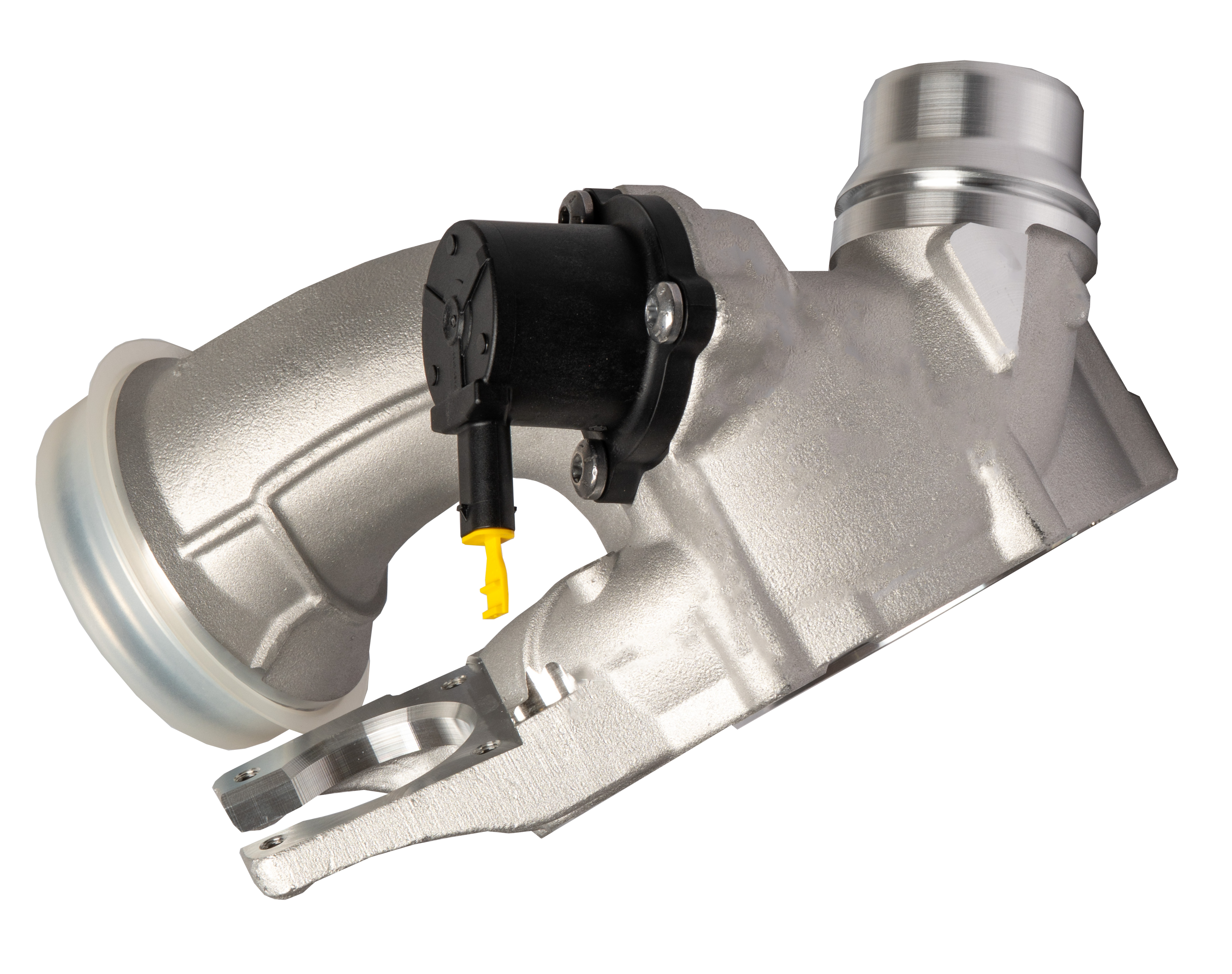

Connector & Interface Protection

Our caps and plugs shield HV and LV connectors from dust, moisture, and mechanical damage, ensuring safe energy transfer and signal integrity across the battery system.

Thermal Interface Sealing

We provide robust protection for cooling plates, SAE/VDA spigots, and refrigerant loops, preventing leaks and contamination in critical thermal management zones.

Cleanroom-Compatible Solutions

All components are produced in ISO 14644-compliant environments and support VDA 19.1 standards, ideal for pouch and prismatic cell assembly lines.

Designed for Safe Handling

Our solutions feature flanges, grips, and ergonomic designs that support gloved handling in HV-protected areas — enabling safe, efficient integration on automated lines.

- Edited.png)

.png)

.png)

Full service. Always.

Complete protection and services at every stage

We Are Your Partner for Efficient and Reliable Supply. This is our offering and our ambition is to be your preferred full-service protection solution partner.

Integrated Packaging & Supply Chain Solutions

We offer ESD packaging, custom labeling, and EDI integration for efficient, high-quality support.

Our reusable KLT containers and customizable packaging boost supply chain efficiency and sustainability.

Quality Management and PPAP

DBI is certified to ISO 9001, IATF 16949, and ISO 14001, ensuring compliance and quality.

We use PPAP and our APQP database to support validated, transparent development.

Reliable ESD Safety Protection

Protecting sensitive automotive components from electrostatic discharge during handling, transport & storage.

Our solutions ensure compliance with industry standards and safeguard the reliability of high-voltage and electronic systems.

Advanced Cleanroom Solutions

Ensuring optimal protection and cleanliness for sensitive automotive components.

Our advanced cleanroom solutions maintain controlled environments to safeguard the integrity of high-precision systems.

Explore Our Protection Solutions

Do you need advice?

Learn how our full service can add value to your business

Matching applications to mobility

We are application specialist. We are familiar with each segment's unique challenges, form assembly conditions to ergonomics.

.png)

.png)